Introduction: A New Way of Making Shoes

Footwear brands across the world are exploring better, faster, and greener ways to make shoes. Because of this shift, 3D-Printed Shoes: The Next Big Thing has become a major topic in the fashion and sports industry. Unlike regular shoes made with cutting and stitching, 3D-printed shoes are built layer by layer using special printers.

According to Fashion Audit,

“3D printing will change how shoes fit, how long they last, and how quickly brands can launch new designs.”

1. Why 3D-Printed Shoes Are a Big Deal

3D-printed shoes are special because they do not follow the old way of making footwear. Instead, brands design them on computers and print the parts directly.

Simple Benefits

- Less waste

- Light materials

- Clean, neat design

- Better shapes

- Faster testing of new ideas

As a result, designers can build shoes that look fresh and feel different.

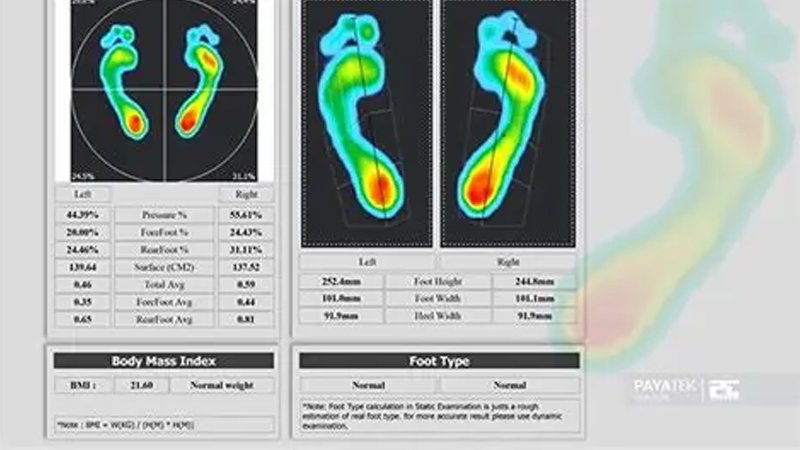

2. Better Fit With Custom Shapes

One of the biggest promises of 3D-printed shoes is the custom fit. Instead of choosing only standard sizes, people can get shoes shaped perfectly for their feet.

Custom Fit Features

- Better arch support

- Pressure-based cushioning

- Fit options for wide or narrow feet

- Natural foot shape design

Because of this improvement, walking and running feel more natural and more comfortable.

3. 3D Printing Supports a Greener Future

A major reason behind the rise of 3D-printed footwear is sustainability. Traditional shoe-making creates a lot of waste, but 3D printing reduces it.

Eco Benefits

- Minimal leftover material

- Recyclable printing filaments

- Less glue and chemicals

- Lower carbon footprint

Since more buyers prefer eco-friendly products, this method will grow quickly.

4. Lattice Midsoles Make Shoes Softer and Stronger

3D printing allows brands to use lattice designs instead of foam. These open patterns offer strong support and great bounce.

Why Lattice Soles Work Well

- They absorb impact

- They feel light

- They support the heel

- They stay strong for years

Therefore, many brands use lattice soles in sports and running shoes.

5. Faster Production Means Faster Trends

Traditional shoemaking takes time because many parts are stitched, cut, and glued. However, 3D printing skips most of these steps.

How This Helps

- Quicker designs

- Faster testing

- On-demand printing

- Less stored inventory

Because fashion changes quickly, brands benefit from this speed.

6. 3D Printing Helps Medical Footwear Too

The technology is also useful in the medical field. Doctors can create custom shoes and insoles for people who need special support.

Medical Uses

- Custom insoles

- Shoes for flat feet

- Shoes for foot pain

- Diabetic-friendly designs

Since each pair can be printed based on the foot shape, support becomes much better.

7. Popular Brands Leading This Change

Several global brands have already released 3D-printed footwear. Their early designs show what the future may look like.

Brands Using 3D Printing

- Adidas 4D

- New Balance 3D midsoles

- Under Armour ArchiTech

- Nike (3D prototyping)

- Reebok Liquid Factory

These pairs are often lighter, softer, and stylish.

8. India’s Market Is Growing Fast

India is slowly entering the 3D-printed footwear space. As sneaker culture grows and buyers want modern designs, the demand will increase.

Why India Is Ready

- Strong interest in sneaker fashion

- Large fitness community

- Rising demand for comfort

- Younger buyers want new tech

- Growing eco awareness

Because of these trends, 3D-printed shoes will soon gain a bigger place in India.

9. Challenges Slowing Down 3D-Printed Footwear

Even with many benefits, a few issues still limit mass production.

Current Problems

- High cost

- Fewer printing materials

- Limited colour options

- Fewer printers available

- Lower supply in India

However, these issues are reducing each year as technology improves.

10. What the Future Will Look Like

By 2030, 3D printing will be common in footwear stores. People may even print their own shoes at local shops.

Future Predictions

- Fully recyclable shoes

- Custom soles for every buyer

- AI-created designs

- Hyper-light materials

- In-store printing stations

As Fashion Audit explains,

“Future shoes will match your feet, your lifestyle, and your style—because they’ll be printed just for you.”

FAQs About 3D-Printed Shoes: The Next Big Thing

1. Are 3D-printed shoes strong?

Yes. New materials make them durable and long-lasting.

2. Are they more comfortable?

Often yes, especially lattice soles and custom fits.

3. Will they replace regular shoes?

Not fully, but they will become popular for running, walking, and lifestyle wear.

4. Are they eco-friendly?

Yes. They reduce waste and use recyclable materials.

5. Does Fashion Audit recommend them?

Yes — Fashion Audit believes they are a smart step toward future footwear.

Conclusion: The Future of Footwear Is Already Here

The 3D-Printed Shoes: The Next Big Thing trend shows how much footwear is changing. With better fit, greener materials, and faster production, 3D printing is shaping a new era of comfort and design.

As Fashion Audit concludes,

“3D printing is not just new—it’s the next big move for smart, comfortable, and eco-friendly footwear.”

Disclaimer:

All trademarks, logos, product names, and brand identifiers mentioned on FashionAudit.com are the property of their respective owners. They are used solely for the purpose of product review, comparison, and consumer information. FashionAudit.com does not claim any ownership of these marks.

No copyright or trademark infringement is intended. If any brand or rights holder believes their intellectual property has been misused, they can contact us directly and we will address the issue promptly.